New innovation from SmartPipe for cleaning ship waste water systems

Our biological cleaning method has been successfully used on ships for many years. In this method, automatic dispensers are installed at the end of each pipe and a biological solution containing the right cocktail of bacterial strains to eat the organic waste, prepared by SmartPipe, is fed into the pipe at regular intervals. The cleaning method is highly effective, whether it is a vacuum line or a traditional gravity system. The bio-solution is effective in removing residues from pipes and cleaning grease, oils and food waste from kitchen waste water lines.

Cleaning the ship’s waste water system

At sea, ships’ sewage systems are usually underpressurised. In practice, this means that the material in the pipe system, consisting of faeces, paper and other waste, moves forward under vacuum.

It is clear that such a system has certain drawbacks, the most significant of which is the accumulation of residues on the walls of the pipes. Because of the risk of blockages, pipes must be cleaned regularly. One traditional method is acid cleaning of pipes. Acid cleaning is done by draining the pipes and filling them with strong acid, which is allowed to act for a certain period of time. Finally, the acid is rinsed off. The operation is very demanding and heavy. In addition, there are many safety risks associated with the method. The acid used requires treatment as hazardous waste, adding to the cost of an already expensive process.

At SmartPipe, we have already replaced the cleaning process with a microbial solution and achieved excellent results. Regularly dispensed, the bacteria solution keeps pipes clean, which significantly saves the shipyard maintenance costs. You can find out more about the topic in our Development Director Mikko Eskola’s LinkedIn articles.

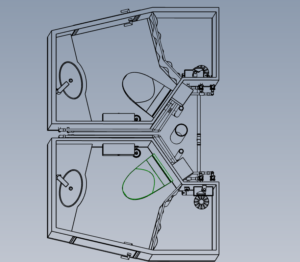

However, there is still one area of the ship’s waste water system that we wanted to develop a solution for: the toilet and other sanitary facilities. Toilets and sinks often cause technical problems and odours, which also affect the customer experience. There are hundreds of toilets in daily use on board.

© SmartPipe System Oy

A cost-effective and simply smart solution

On-board toilets are cleaned daily. For cleaning, the traditional cleaner is applied to the toilet by dispensing 10-20 ml of the product and applying it with a brush. These products are well suited for traditional hygiene maintenance, but they do nothing for the plumbing components and also cause foam problems in the plumbing.

We found a cost-effective overall solution for our customers to further reduce the amount of hazardous chemicals on board. It is an advanced solution that cleans both toilets and pipes with a bio-solution.

Our solution is simply smart. We’ve replaced the traditional cleaner with a dual-function solution that works both as a toilet cleaner and keeps the toilet’s plumbing components free of residue. This saves even more effort and money without the need to add extra cleaning agents to the toilet units, as is currently the case. In any case, when cleaners clean toilets every day, they only need to change the cleaner they use with SmartPipe’s advanced 2-in-1 product.

Our unique product is called BioTroop Sani. The product cleans and, with continuous use, prevents problems in the maintenance of the ship’s plumbing from the toilet to the end of the plumbing. The solution combines a moderately acidic, biodegradable solution with a pipe limescale prevention and removal technique. Performance requires carefully selected surfactants with a pH of 3-4. As the cleaning process progresses, the pH value inside the pipe rises to a higher level downstream. When the black water eventually enters the biological treatment system, it does not affect the performance of the systems as traditional chemicals do. The solution is also low foaming, further reducing the use of antifoaming agents.

We develop different types of solutions for biological wastewater treatment systems for ships and buildings. Biotroop Sani is now on sale and part of our comprehensive family of plumbing products. Ask more.

Follow our Business Development Manager Mikko Eskola on LinkedIn .