Wastewater treatment system commissioning applications

Maintenance and Start-up of Ship Wastewater Treatment Plant Requires Bacteria

The wastewater treatment plant on all ships is either shut down for seasonal maintenance or started up for the first time. Due to seasonal variations, the number of passengers can be quite low, resulting in weak biomass in the biological treatment plant, which cannot meet the required treatment standards.

A drawback of every biological treatment plant is that it cannot be technically "slowed down". Biological treatment either occurs or does not occur. All wastewater treatment processes depend heavily on the activity of the biomass.

Starting up the system can be done in various ways, some of which may prove difficult due to insufficient waste feeding, such as after a ship's dry dock. Here we introduce the traditional method for maintaining ship wastewater treatment systems, as well as SmartPipe's advanced and eco-friendly solution.

The Importance of Healthy Bacterial Biomass

In ideal conditions, the biomass of wastewater treatment plants should contain dynamic, diverse, and stable microorganisms working together to reduce organic load and meet treatment standards. Bacteria are the most important microorganisms in biomass, as they are responsible for the complete (oxidation) or partial (fermentation) breakdown of organic materials (COD/BOD). The biomass also includes yeasts and fungi.

Seeding Treatment Systems with the Traditional Method

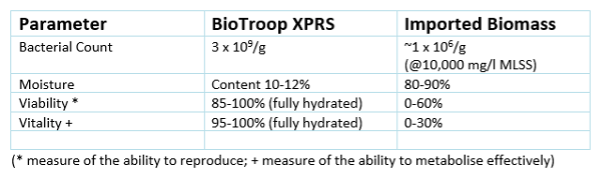

Maintenance and start-up of wastewater treatment systems are traditionally done by introducing active biomass from another system. The method is functional but has several drawbacks concerning the "raw material quality" and start-up schedules. Additionally, it requires significant resources, as the biomass is transported to ships by tanker trucks, increasing start-up costs. Despite the large amount of biomass, the number of beneficial bacteria may be surprisingly low. The biomass is not very uniform and the technology is outdated. This is also why many wastewater treatment plants are willing to share their biomass with others.

Eco-Friendly Solution for System Maintenance and Start-up

SmartPipe's solution for maintaining and starting up wastewater treatment systems is simply intelligent and does not require bringing biomass to the ship by tanker trucks. BioTroop XPRS is a biological booster designed specifically for ship wastewater treatment plants.

BioTroop XPRS is a biological booster designed specifically for ship wastewater treatment plants. The solution is compact and easy to use, packaged in dry bags, with bacteria carefully selected to function in wastewater systems. These bacteria are metabolically diverse and quickly degrade organic matter. The activity of BioTroop XPRS can be easily adjusted in specific cases by adding other products from SmartPipe's BioTroop series to the wastewater treatment plant.

How Does BioTroop XPRS Work?

BioTroop XPRS provides assistance in activating biomass. Subsequently, bacteria need a growth medium in the absence of sewage. There are several ways to create a growth medium, depending on whether one plans to start from a completely filled tank (and grow the biomass for 10-12 days) or start, for example, at 25% capacity and increase flow to 50 % > 75 % > sewage within the first 10 days.

SmartPipe recommends the latter method and favors molasses as a growth medium for bacteria. Molasses BOD (biological oxygen demand) typically ranges from 900 g/l (76% sugar).

If biomass growth is slower than expected, it is usually due to some toxic substance (biodegradable agents, cleaning agents, etc.). It is good to note this by reducing the amount of cleaning agents on the ship and optimizing the range of materials used so that the work is carried out efficiently with substances that do not adversely affect the wastewater treatment system.